Description

Linbay Roller Shutter Slat roll forming machine is to make roller shutter slat, PU slat (fire curtain) and venetian blind for Garage Doors, Commercial Counter Shutter, Commercial fire door, industrial , office public, Kiosks, pavilions, windows etc. Machinable steel material can be galvanized steel,stainless steel (304 and 316),aluminum, Ral etc. The steel thickness range could be Gauge 16, Gauge 18, Gauge 20, Gauge 22, Gauge 24, which is widely used in America, or could be 0.6-1.5mm at international market.

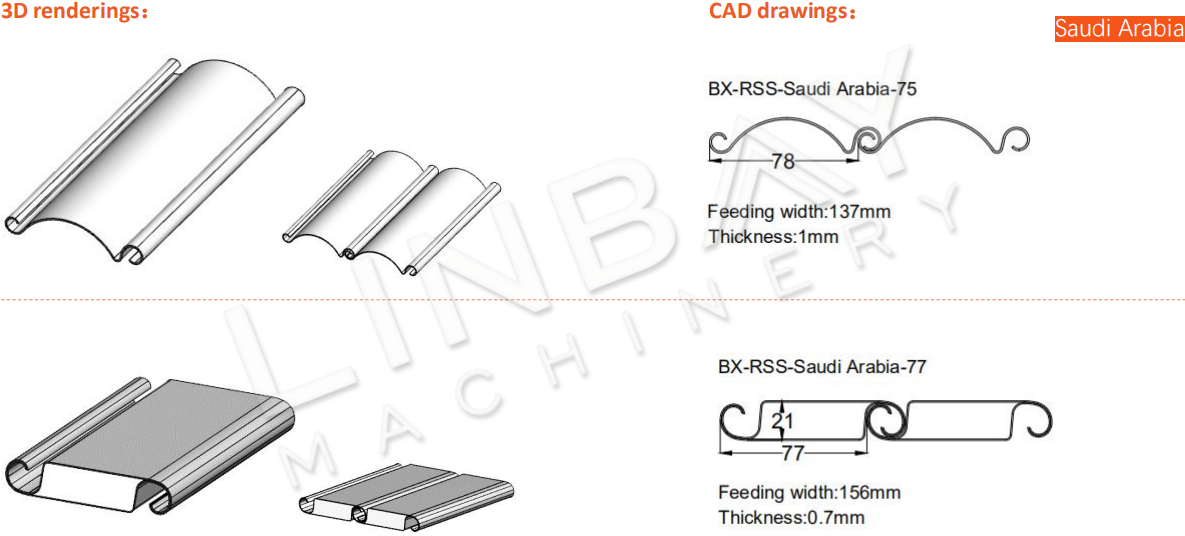

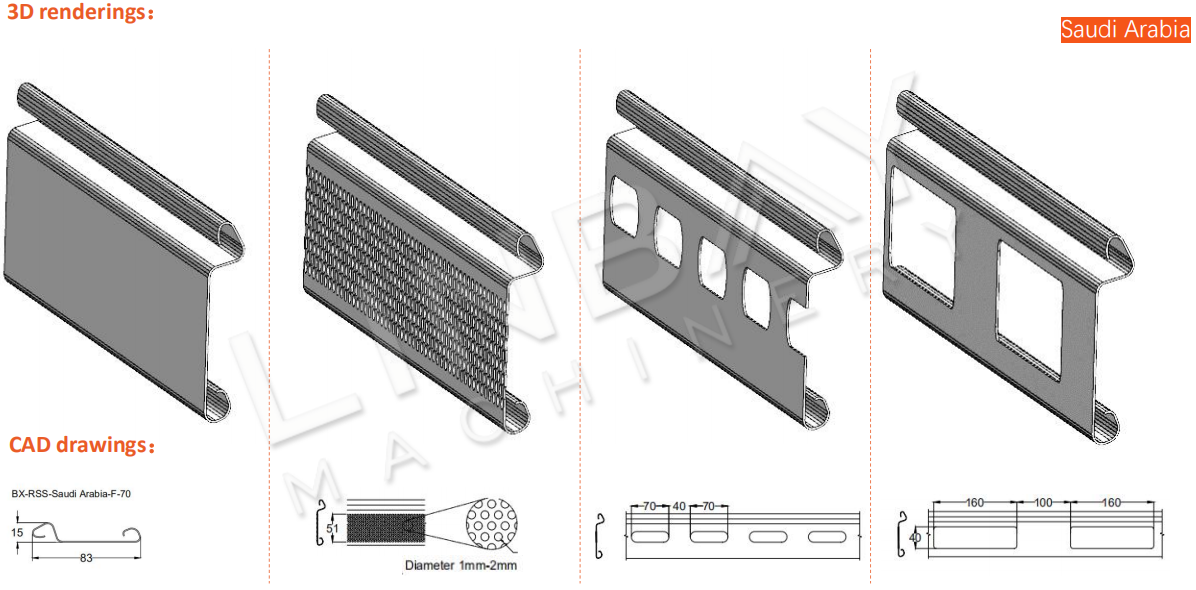

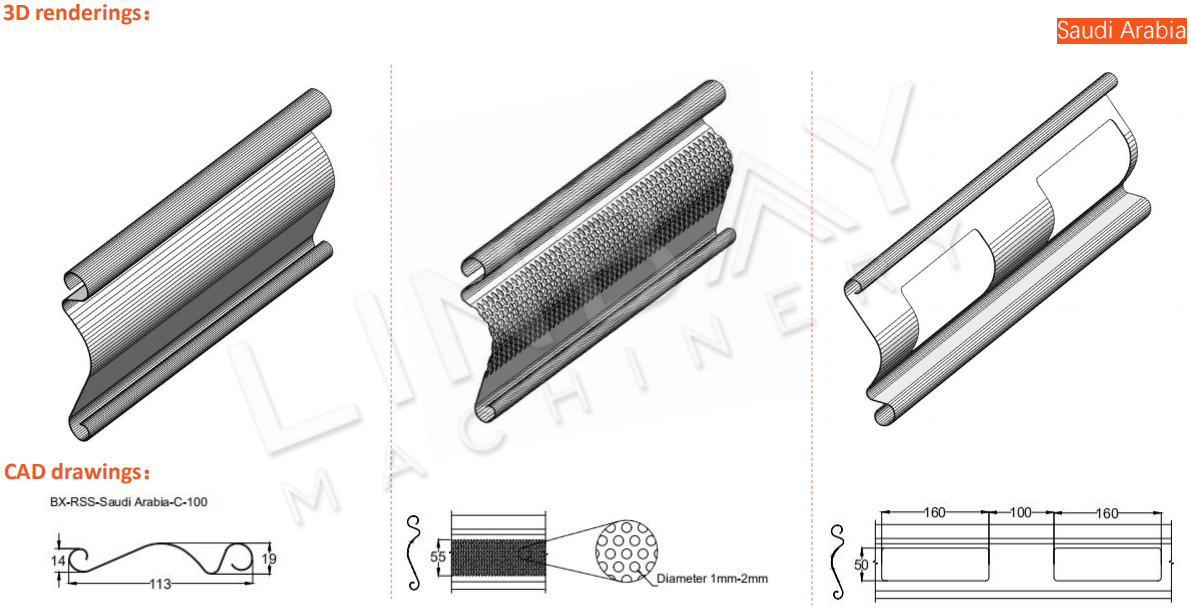

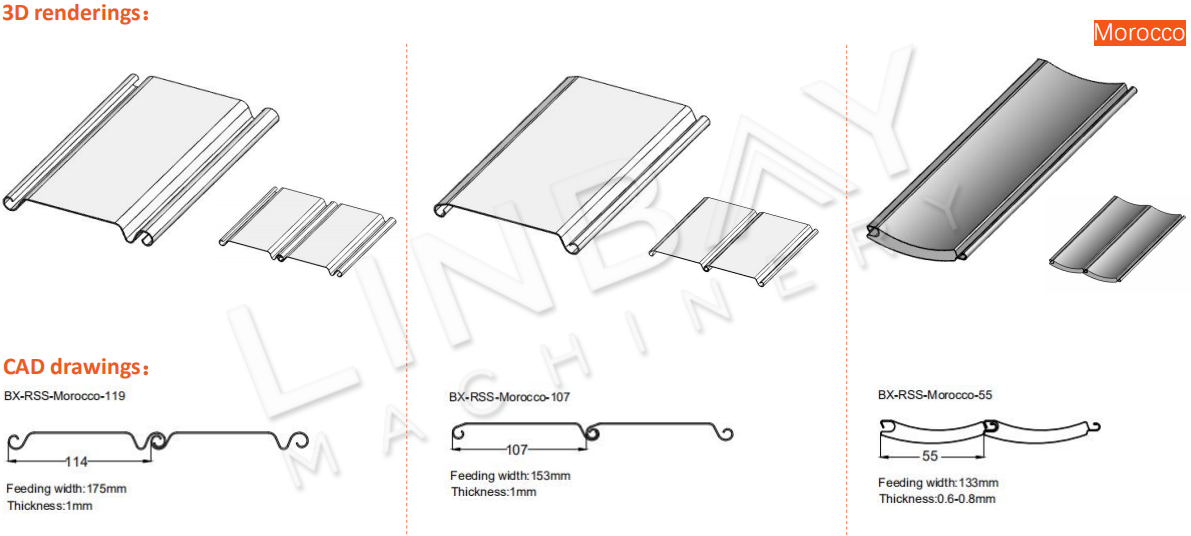

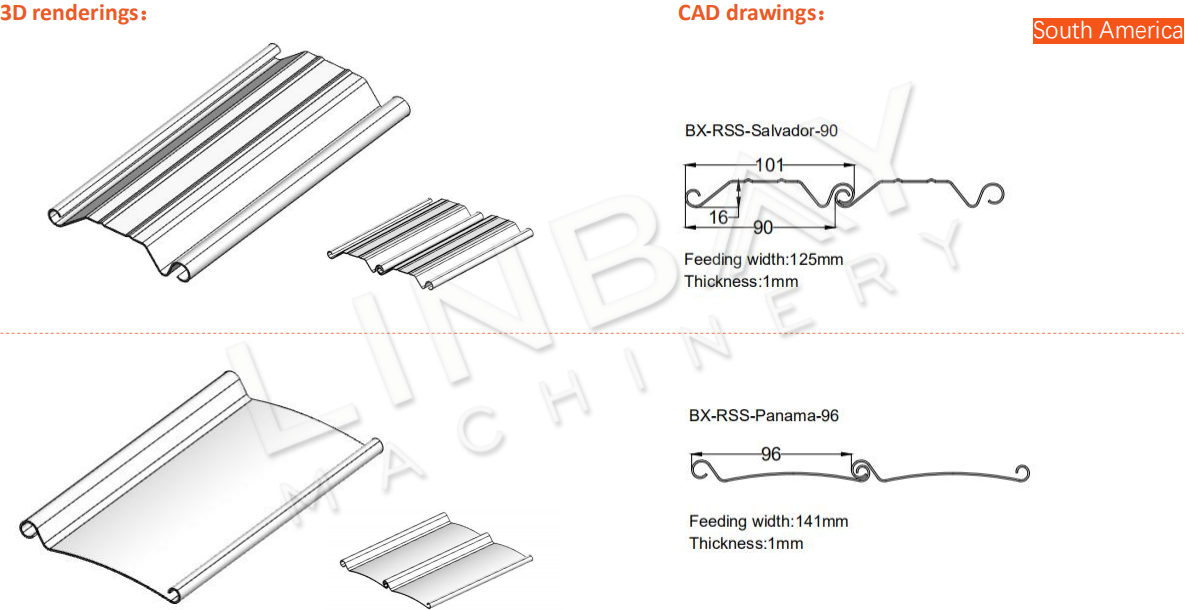

Popular profile: flat slat, curved slat, perforated slat, 55 foam slat, 77 foam slat, 90 foam slat, C50 venetian blind, C80 venetian blind and Z90 venetian blind.

Linbay could prepare any kinds of roller shutter slat roll forming machine and meet your high-precision requirements, making surface pretty and burr-free also high-precision punch holes, specially for micro- perforation slat, we could make 0.3mm tolerance for holes’ distance with servo feeder system. In roller shutter slat industry roll forming machine could also produce other accessories like: ① Octagonal tube ② Rail for slat door ③ Guide channel ④ Bottom bar: I-bottom bar, T-bottom bar and L-bottom bar. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles

Application

Real Case A

Description:

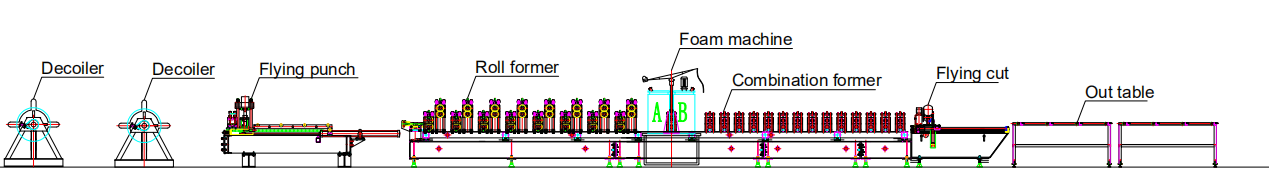

Case A and Case B are two lines with advanced IPC&PLC control cabinet, it has 20GB memories and it has Software able to program a complete batch of typical jobs. Now we are promoting this kind of control at all Linbay’s roll forming machines.

Case A is a proper chart for foam shutter slat, whole line has no stop, working speed could be around 10m/min.

Real Case B

Description:

Case A and Case B are two lines with advanced IPC&PLC control cabinet, it has 20GB memories and it has Software able to program a complete batch of typical jobs. Now we are promoting this kind of control at all Linbay’s roll forming machines.

Case B is a double-row shutter slat, one machine could produce 2 profiles, and it has 3 types of punch in the middle and two kind of end lock holes, with micro-perforation, working speed could be 8m/min.

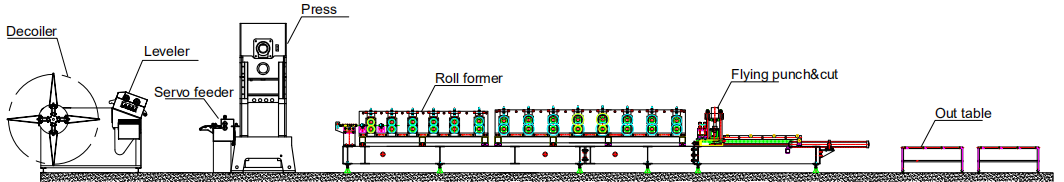

Whole Production Line of Rolling Shutter Slat Roll Forming Machine

Technical Specifications

| Rolling Shutter Slat Roll Forming Machine | ||

| Machinable Material : | A) Galvanised Steel | Thickness(MM):0.5-1, 0.6-1.2, 0.8-1, 1-1.5 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN) | 0-20 | * Or according to your requirement |

| Forming stands : | 12-16 stands | * According to your profile drawings |

| Decoiler : | Manual decoiler | * Hydraulic decoiler or double head decoiler(Optional) |

| Punching system | Hydraulic punching station | * Punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station Or torri stand structure (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

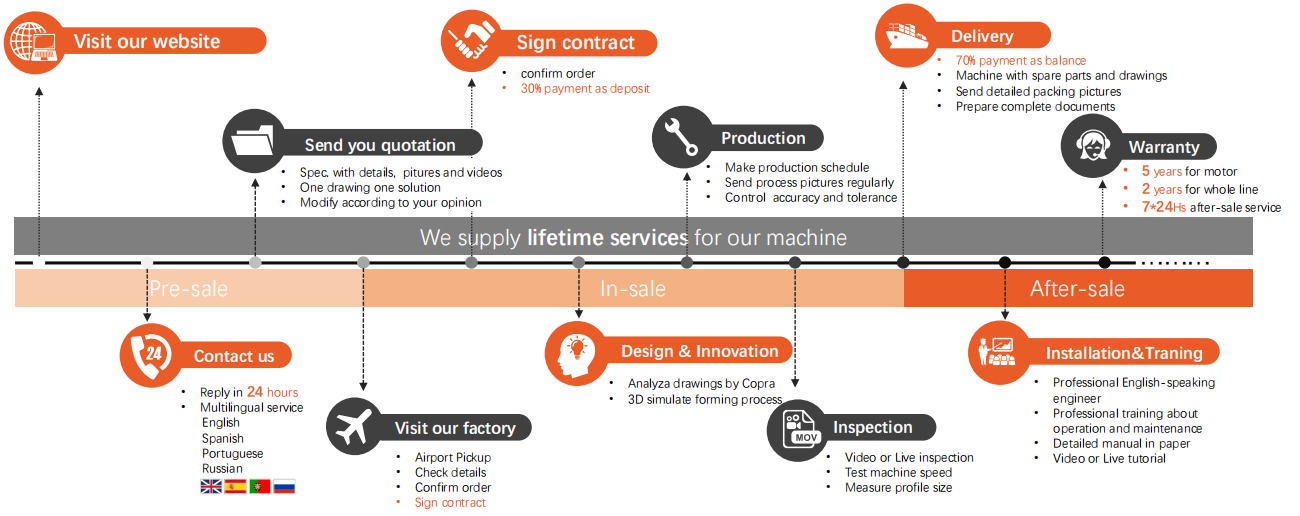

Purchase Service

Q&A

1. Q: What kinds of experience do you have in producing rolling shutter slat roll forming machine?

A: We have many experience in rolling shutter slat roll forming machine, we have exported flat slat roll forming machine, foam slat roll forming machine, blind panel roll forming machine to many countries, such as: Norway, UAE, Iran, Israel, Saudi Arabia, Turkey, Russia, India, Mexico, Peru, Brasil, Salvador, Panama, Morocco, New Zealand etc.

In roller shutter slat industry Linbay’s roll forming machine could also produce other accessories like:

①Octagonal tube; ② Rail for slat door; ③ Guide channel; ④ Bottom bar: I-bottom bar, T-bottom bar and L-bottom bar.

2. Q: What are the advantages do you have?

A: We have our own factory, we are 100% manufacturer, so we could easily control the delivery time and machine quality, offering you the best Chinese after-sales service. Besides, our innovative team is well educated with bachelor degree, who could also talk in English, realizing smooth communication when he comes to install your machine. He has more than 20 years of experience and could solve any problem alone during his work. Next, our sales team will always takes care of your every needs to make a one-to-one solution, giving you professional idea and suggestion to let you get an affordable and practical producing line. Linbay is always your best choice of roll forming machine.

3. Q: What is the delivery time of rolling shutter slat roll forming machine?

A: We need to take around 60 days from machine design to assemble it. And the exact delivery time should be confirmed after checking door frame drawing.

4. Q: What is the machine speed?

A: For foam slat roll forming machine normally line speed is around 0-10m/min.

For blind panel and flat shutter or curved shutter line speed could be 0-20m/min.

For micro-perforation slat line speed is 8m/min with punch press.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching molds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.